Understanding: 5 Benefits of HDPE Odor Control Flap Valves

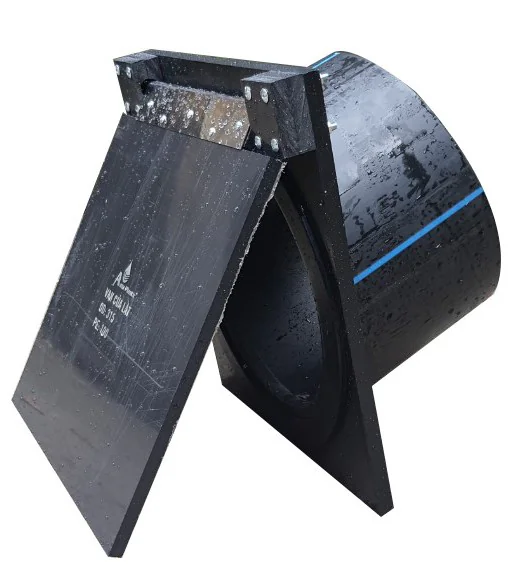

HDPE Odor-Blocking Flip Gate Valve is specially designed to open and close based on airflow or wind direction, helping to prevent odors from escaping from drainage systems to the outside or vice versa. Made from HDPE (High-Density Polyethylene), this valve offers long durability, good chemical resistance, and adapts well to various environmental conditions.

In this article, we will explore the outstanding benefits of the HDPE odor-blocking flip gate valve, how to choose the right one, and its practical applications in daily life.

Benefits of HDPE Odor-Blocking Flip Gate Valves in Drainage Systems

Modern drainage systems require equipment that controls odors and prevents the leakage of harmful gases. The HDPE odor-blocking flip gate valve has become an indispensable part of these systems due to its many advantages. In this section, we will analyze each benefit based on its technical characteristics and real-world usage.

Key benefits include excellent oxidation resistance, high durability, effective sealing, easy installation, and long-term economic value. These strengths give engineers, contractors, and investors confidence when choosing this product for construction or renovation projects.

We will explore each specific benefit below.

Oxidation Resistance and High Chemical Resistance

During operation, drainage systems are continuously exposed to various chemicals such as acids, alkalis, salts, or strong cleaning agents. Therefore, the valve material must have excellent corrosion resistance to maintain long-term efficiency.

HDPE, or high-density polyethylene, is the ideal material for this purpose. Its non-polar molecular structure helps limit the effects of corrosive chemicals. This means the HDPE odor-blocking flip gate valve not only retains its shape and size over time but also does not degrade or rot due to environmental impacts.

Additionally, the oxidation resistance of HDPE helps the product adapt perfectly to wet, hot, or environments with high humidity. This is especially important in drainage systems, both indoor and outdoor, where environmental factors often change.

High Durability and Exceptional Mechanical Strength

One of the key factors in choosing a flip gate valve is the product's durability and lifespan. With HDPE material, the HDPE odor-blocking flip gate valve has excellent resistance to impact and vibration during operation.

Typically, HDPE valves can operate reliably for many years, even up to 15-20 years, without the need for major replacements or repairs. This is a significant advantage for businesses or households looking to minimize maintenance costs and enhance system efficiency.

Additionally, thanks to HDPE's inherent flexibility, the product is less likely to crack or warp under strong impacts or sudden temperature changes. In practice, HDPE valves maintain their shape even under heavy loads or in harsh environments.

Effective Odor Prevention and High Sealing Performance

One of the main functions of the HDPE odor-blocking flip gate valve is its ability to prevent toxic gases from escaping the system or entering it. The valve's design allows it to self-seal when there is no airflow while opening when pressured air pushes through.

This ensures the system remains sealed, preventing unpleasant odors or environmental contamination. Rubber seals and accompanying accessories enhance the valve’s sealing ability, minimizing gas leaks.

In fact, many customers have reported that after installing the HDPE odor-blocking flip gate valve, odors from drainage systems were significantly reduced, improving the quality of living and working environments. Furthermore, the sealing ability also helps limit the spread of bacteria and pathogens from exhaust gases, contributing to public health protection.

Easy Installation and Maintenance, Environmentally Friendly

![]()

Installing the HDPE odor-blocking flip gate valve is simple and compatible with many different piping systems. Thanks to its standard design, technicians or installers can perform the installation quickly without requiring complex techniques or specialized tools.

Additionally, this product does not require complex routine maintenance. When cleaning is necessary, simply remove it for cleaning or easily replace the accessories without significantly affecting the entire system. This helps reduce maintenance time and costs, improving operational efficiency.

Environmentally, HDPE is a recyclable material that does not cause pollution when processed or recycled after its service life. This product is eco-friendly, meeting increasingly strict environmental protection standards.

Practical Applications of HDPE Odor-Blocking Flip Gate Valves in Life and Industry

Beyond its technical and economic benefits, the HDPE odor-blocking flip gate valve has many diverse applications in daily life and various industrial sectors. This section will introduce typical examples across different fields.

Common applications include installation in domestic drainage systems, industrial systems, wastewater treatment plants, high-rise buildings, hospitals, laboratories, food processing plants, warehouses storing volatile or odor-causing goods, entertainment areas, and even commercial housing projects.

We will delve into each sector, analyzing how the HDPE odor-blocking flip gate valve contributes to improving operational efficiency and ensuring hygiene safety.

Applications in Domestic and Urban Drainage Systems

In construction projects, drainage systems play a crucial role in ensuring a clean, airy, and pollution-free living environment. Using the HDPE odor-blocking flip gate valve in these systems helps effectively control exhaust gases while reducing odors from spreading to the external environment.

Installing the valve in places such as toilet drains, bathrooms, and sump pits ensures that gases do not escape through the drainage pipes. This not only helps maintain a healthy living environment but also prevents the spread of bacteria and viruses from the drainage system.

Furthermore, major cities and crowded urban areas are increasingly focusing on odor control solutions to improve the quality of life. HDPE valve technology is suitable for widespread implementation, offering both cost savings and high effectiveness.

Role in Industrial Wastewater Treatment and Environmental Protection

Industrial wastewater treatment requires high technical standards, safety, and environmental protection. Harmful, odor-causing, or potentially water-polluting waste must be tightly managed.

The HDPE odor-blocking flip gate valve is used in wastewater treatment systems to prevent toxic gases from escaping, reducing the risk of harm to workers and surrounding communities. It also helps maintain stable system operation, preventing gas leakage through connections or faulty pipes.

This system is also suitable for use in large-scale factories that require effective and long-lasting gas control over time. Both investors and environmental managers highly value its ability to protect public health and minimize negative environmental impacts.

Installation and Maintenance of HDPE Odor-Blocking Flip Gate Valves

Proper installation is key to the effectiveness of the HDPE odor-blocking flip gate valve. This process includes preparing the pipe system, selecting the proper location, choosing the correct size, and checking the system after installation.

For maintenance, users should regularly check the condition of the rubber seals, clean the flip gate and its accessories. If any signs of leakage are detected, immediate replacement or repair is necessary to maintain optimal odor-blocking performance.

The simple operation and easy maintenance save time and costs, minimizing risks during usage.

Conclusion

From the analysis above, it is clear that the HDPE odor-blocking flip gate valve is an optimal solution, offering outstanding benefits such as high oxidation resistance, excellent durability, effective odor prevention, and environmental friendliness. Particularly suitable for various fields, from domestic and industrial to environmental protection, this product contributes to improving the quality of life and ensuring public health safety. Proper selection and installation will help maximize the benefits of the valve, contributing to the creation of a cleaner, more sustainable, and efficient drainage system in the future.