Composite Grating Floor

I. Introduction

Grating floors are a popular building material widely used across various industries, from construction to heavy industries. Among the types of grating floors, composite grating floors and galvanized grating floors are two common choices. This article will focus on comparing the advantages of Hoa Binh composite grating floors with galvanized grating floors, helping readers get an overview and choose the one that best suits their needs.

II. Hoa Binh Composite Grating Floor

1. Concept and Structure

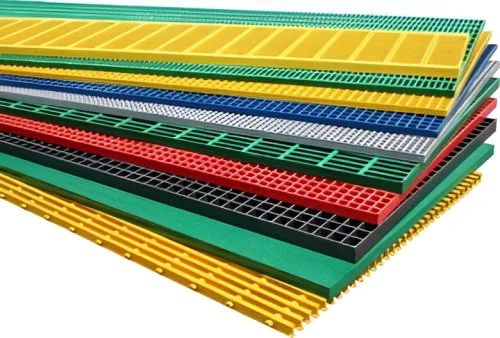

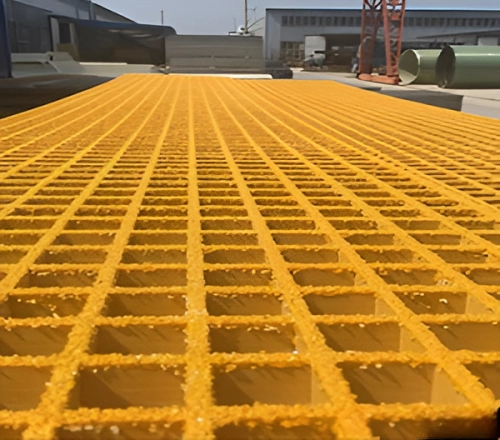

Composite grating floors are made from composite materials, typically a combination of fiberglass and epoxy or polyester resin. This is an advanced material widely used due to its superior durability and aesthetic qualities.

2. Advantages of Hoa Binh Composite Grating Floor

a. High Durability and Long Lifespan

Composite grating floors are highly durable, capable of withstanding strong impacts without deforming. This is due to the combination of fiberglass and resin, which gives the material better resistance to mechanical forces compared to galvanized grating floors.

b. Corrosion Resistance and Chemical Resistance

One of the biggest advantages of composite grating floors is their ability to resist corrosion and chemicals. In industrial environments, where frequent exposure to corrosive chemicals occurs, composite grating floors outperform galvanized grating floors, which can corrode over time, even with the protective galvanizing coating.

c. Lightweight

Composite grating floors are much lighter than galvanized grating floors. This not only makes them easier to transport and install but also reduces the load on building structures, especially in projects with strict load-bearing requirements.

d. Safety and Non-conductive

Composite grating floors are non-conductive, which is important in environments with fire or explosion risks or where high electrical safety standards are required. Additionally, composite floors have better anti-slip properties, reducing the risk of accidents for workers.

e. Easy Installation and Maintenance

Composite grating floors are easy to install and maintain due to their lightweight and good load-bearing capacity. The lack of a need for galvanizing or coating also helps reduce long-term maintenance costs.

III. Galvanized Grating Floor

1. Concept and Structure

Galvanized grating floors are made from steel and coated with zinc to prevent corrosion. This type of floor is common in many industrial applications due to its durability and good load-bearing capacity.

2. Advantages of Galvanized Grating Floor

a. Good Load-Bearing Capacity

Galvanized grating floors have excellent load-bearing capacity, making them suitable for areas that require large load support, such as factories, warehouses, or transportation structures.

b. Low Cost

One of the reasons galvanized grating floors are widely used is their relatively low production and installation costs compared to composite grating floors. This is particularly important for projects with limited budgets.

c. Anti-slip Capability

Galvanized grating floors also have good anti-slip properties, especially when designed with anti-slip patterns, ensuring safety for users.

d. Easy to Fabricate

Steel is an easy material to process, cut, bend, and weld, allowing galvanized grating floors to be customized according to specific project requirements.

IV. Comparison of Hoa Binh Composite Grating and Galvanized Grating Floors

1. Durability and Lifespan

Although both types of floors are durable, Hoa Binh composite grating floors have an advantage in withstanding mechanical impacts and harsh environments. Galvanized grating floors can corrode over time, especially in chemical environments, while composite floors maintain long-term durability.

2. Corrosion Resistance

Hoa Binh composite grating floors excel in corrosion resistance. The resin and fiberglass are unaffected by corrosive chemicals such as acids, alkalis, or salts, whereas galvanized grating floors, despite the protective coating, can still corrode after prolonged use.

3. Weight and Installation

Hoa Binh composite grating floors are much lighter than galvanized grating floors. This not only makes them easier to transport and install but also reduces the load on structural components. This is especially important for renovation projects or elevated structures.

4. Safety

In terms of safety, composite grating floors have the advantage of being non-conductive and have better anti-slip properties, reducing the risk of accidents in the workplace. Galvanized grating floors also offer anti-slip features but lack the electrical insulation properties of composite floors.

5. Cost

Galvanized grating floors typically have a lower initial investment cost, making them suitable for projects with limited budgets. However, maintenance and replacement costs for galvanized grating floors may be higher due to corrosion over time. On the other hand, Hoa Binh composite grating floors have a higher initial investment cost but are less expensive to maintain in the long term.

V. Applications of Hoa Binh Composite Grating and Galvanized Grating Floors

1. Applications of Composite Grating Floors

Hoa Binh composite grating floors are commonly used in industries requiring high durability and corrosion resistance, such as chemical, oil and gas, and coastal areas. Additionally, composite floors are used in construction projects that require high safety standards, such as residential buildings and transportation infrastructure.

2. Applications of Galvanized Grating Floors

Galvanized grating floors are typically used in areas that require high load-bearing capacity, such as factories, warehouses, industrial plants, and transportation structures. With their low cost and good load-bearing capacity, galvanized grating floors are a popular choice for many projects.

VI. Conclusion

Hoa Binh composite grating floors and galvanized grating floors each have their own advantages and disadvantages, suitable for different usage needs. Hoa Binh composite grating floors stand out with their high durability, corrosion resistance, lightweight, and safety features, making them an optimal choice for harsh environments and safety-critical applications. In contrast, galvanized grating floors have an advantage in lower initial investment costs and good load-bearing capacity, making them suitable for projects with limited budgets and high load-bearing requirements.

The choice of grating floor type depends on the specific factors of each project, including the usage environment, technical requirements, and budget. Understanding the advantages of each type of grating floor will help investors and contractors make optimal decisions, ensuring both economic and technical effectiveness for the project.