Comparison of Differences Between Cast Iron Manhole Covers and Composite Manhole Covers – Key Differ

Compare the Differences Between Cast Iron Manhole Covers and Composite Manhole Covers

What is a composite manhole cover?

A composite manhole cover is also known as a composite drain cover. It is a product made from composite material; consisting of synthetic resin mixed with various raw auxiliary materials and chemicals; thus unlike ordinary plastic. This compound is mixed from Polimal resin, reinforcing fiber, load-bearing material, fiberglass cloth, natural stone, Mepox, and some other additives... After being mixed with a suitable formula; they undergo a chemical reaction and create an extremely durable, resilient compound... called composite.

The composite drain cover supplied by Hoa Binh Construction Company is of good quality; durable, aesthetically pleasing, diverse, rich in designs, colors, and is affordably priced and meets standards.

Composite manhole covers have many advantages

Manhole covers made from composite material have many advantages. The product is lighter compared to traditional manhole cover materials like cast iron, steel, or concrete. In addition, this manhole cover has several advantages as follows:

Excellent anti-theft, rich and diverse designs and colors

The entire mixture of cast iron, steel, and other metals used to cast manhole covers can be recycled; they have a relatively high purchase price. Therefore, the situation of manhole cover theft is common and frequent nationwide. According to statistics in Hanoi, many manhole covers are lost; an average of about 10 manhole covers are stolen every night. This situation greatly affects the safety of the drainage system; posing danger to people, animals, and passing vehicles. At the same time, it impacts costs.

To overcome this situation, high-quality composite manhole covers with good durability have been researched and produced to completely solve this problem. With the inherent durability and resilience of composite material, which is difficult to recycle and has a low recovery value, the problem of cast iron drain cover theft has been thoroughly limited. The product's introduction is the most effective solution to the situation of manhole cover theft.

That is also the reason why many people currently use composite drain covers instead of products cast from iron as before. It will be the perfect choice in the near future. Especially in the era of industrialization, where high aesthetics and modernity are needed.

Composite vs. Cast Iron Manhole Covers: Rich and diverse design and color

Besides the outstanding feature above, this type of composite drain cover is very diverse; rich in designs, colors, and manufacturing designs. Due to the main characteristic in the product manufacturing stage being manual methods; combined with advanced technology in the formulation of raw auxiliary materials... The mold creation, sample making, and design of product shapes and colors are always actively managed. The product meets almost all strict requirements regarding design, specifications, quantity, and product output quality.

This is also considered a major advantage that makes many people choose composite manhole covers; composite drain covers to install for their projects.

Composite manhole covers, composite drain covers are easy to transport, easy to construct

Unlike manhole covers made of cast iron and steel; composite manhole covers are very light. The weight of this type is only 1/4 of cast iron and steel manhole covers. Therefore, the product is very convenient for transportation, installation, and construction activities. This also increases safety; flexibility in the transportation and installation stages at construction sites; saving more time and construction labor. It saves the cost of hiring workers for the job and installation. It minimizes investment costs for infrastructure categories.

The product is an optimal solution for construction contractors.

Composite drain covers are highly heat-resistant, anti-aging

As a product made from synthetic composite material; it goes through a production process that meets international standards and is of high quality. Therefore, composite manhole covers can withstand various high and low temperatures and are resistant to fire and explosion. The product is anti-aging and can withstand corrosion in harsh environmental conditions such as; wetness, alkalinity, salinity... Thanks to these features, composite drain covers can be installed in all environmental conditions.

Therefore, the product is applied in many areas of life. From roads, sidewalks, public places, parking lots to construction projects. The product is also widely installed in households such as balconies, gardens, etc.

Composite manhole covers are ultra-durable, highly load-bearing, and noise-reducing

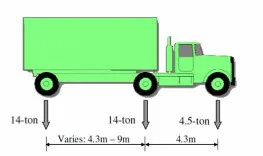

Most of the locations where this type of drain cover is installed are public places with heavy traffic. The types of vehicles on the road vary with many large load capacities. Therefore, the product needs to have the ability to withstand large vehicle loads. And the composite manhole cover meets that condition well. It has a load capacity equivalent to cast iron manhole covers; and is manufactured according to European standards; capable of reaching a compression load level of over 30 - 40 tons.

In addition, compared to cast iron drain covers, the composite product minimizes the noise emitted every time a vehicle passes over.

Thanks to its large load-bearing characteristic, the composite manhole cover has a longer lifespan than other products.

Composite vs. Cast Iron Manhole Covers: Effective odor prevention

Composite drain covers have effective odor prevention capabilities. Gas and foul odors accumulating in the underground drainage system often rise through manholes; drain covers, manhole covers every time it rains or the weather is hot. This causes discomfort and greatly affects the health and daily life of residents. Therefore, the solution of installing odor-preventing composite manhole covers is the optimal option always chosen by residential areas; and cities. Odor-preventing composite drain covers are constructed with a sealed odor-blocking gasket; or a siphon-type odor trap similar to a toilet bowl. This design ensures that foul odors; and gases are completely prevented from rising through urban manhole covers; ensuring a fresh living environment for people.

All the advantages about what a composite manhole cover is, as seen above, show that this is a superior product for the future. This promises to be a new solution for urban infrastructure regarding the use of manhole covers.

Composite Manhole Cover Production Process

The production process for composite manhole covers is not overly complicated. However, to produce a product that is high-quality, highly load-bearing, sharp, durable, beautiful, and also cheap, that is the secret of an experienced craftsman. The production process is as follows:

Product molding

We see many manhole cover designs, from circular, square, to rectangular. So, product molding is the first important step. It is the step that determines the style of each type of manhole cover. It also ensures the product surface is smooth and aesthetically pleasing. Meeting the aesthetic needs of users. Therefore, the step of creating standard product molds is extremely important.

Cleaning the casting mold

After creating the manhole cover casting mold with the necessary technical criteria and shape. The craftsman moves on to another important stage, which is thoroughly cleaning the manhole cover casting mold. This helps when applying the mold release agent easily and does not waste mold-release material. Next, the craftsman will apply the anti-stick layer to the mold surface. This step is necessary and relates to the product's finish. It also helps the demolding process happen easily, making the mold release gentle, avoiding unnecessary impacts that affect the product's structure and quality.

Creating the surface pattern layer of the composite manhole cover

The main purpose of creating the surface pattern layer of the composite manhole cover is to ensure the detail, sharpness, and aesthetics of the product. It helps the product have a beautiful, attractive surface while also achieving resilience and durability for the product. This step requires compounding chemical mixtures to form a Gel mixture that is swept onto the mold surface. The secret formula and ratio of the various chemicals. This Gel raw auxiliary material is a particularly important formula for each manufacturer. Therefore, the quality, resilience, and detail of the composite manhole cover depend greatly on this stage.

Laying the fiberglass core & Gel Base layers

Immediately after applying the Gel to the mold, the next step in composite manhole cover production is laying the fiberglass core. This stage is also extremely important and is the main factor determining the quality and load-bearing capacity of the product. This fiberglass core layer helps the product structure be durable and highly load-bearing. You need to continuously layer the Base layers (consisting of the gel mixture and other raw auxiliary materials) alternating with the fiberglass core layers, ensuring the product thickness adheres strictly to the blueprint standard.

Laying the fiberglass mat and completing the mold assembly

When the Gel Base foundation and fiberglass layers have been laid, reaching the designed thickness, we move on to laying another fiberglass mat to proceed with mold face assembly and final pressing. This stage requires pressing the two mold faces together tightly, without separation or air bubbles between the two mold layers. After pouring and pressing the two mold faces, the product needs to dry completely before the mold can be separated.

Product finishing, load inspection

After being separated from the casting mold, the composite manhole cover product is transferred to the stage of cutting and grinding the edges and surface details. Smoothing the manhole cover surface helps the product achieve high aesthetics and safety during transportation and installation. Before finishing the product, we need to ensure that the fiberglass layers and Gel Base layer are completely dry. The product must be completely dry and hardened before grinding. Otherwise, it will damage the load-bearing structure of the manhole cover.

The finished composite manhole cover product will be put on a compression machine to check durability and load capacity. Only products that meet standards in both quality and aesthetics will be stored and shipped out to the market.

Notes when manufacturing manhole covers

To produce a composite manhole cover product that meets standard quality, load capacity, and aesthetics, besides the secrets regarding technology, dosage, and raw material formula, the craftsman also needs to follow the correct process. The steps need to be carried out in the correct order with standard raw materials. When crafting the sample and casting mold, it is necessary to adhere to the technical drawing to produce the composite manhole cover product according to requirements.

Where is the best place to buy composite manhole covers

To buy the cheapest composite manhole covers, with good quality, high durability, many advantages, good service, and easy transportation...; we need to choose a reputable store that is not too far away. Currently, there are many units supplying and selling composite manhole covers on the market. Therefore, choosing which address offers quality, cheap selling prices, good purchasing policies, and good after-sales service is extremely important. Thus, the assessment of product quality and services will be more objective. The decision to buy cheap composite drain covers will be more reassuring.

There are quite a few units manufacturing composite manhole covers on the market. Hoa Binh Construction Company is one such unit.

What are the advantages of choosing Hoa Binh Construction Company's composite manhole covers?

Processing composite material with high technical proficiency, Hoa Binh Company always increases the durability of the material. Designs are suitable for townhouse projects, streets, and civil companies. There is diversity in designs, giving customers many choices. Hoa Binh Company always has enough quantity to supply for projects because every month the Company produces over 10,000,000 manhole covers of different standard types.

Contact address for Hoa Binh Company?

HOA BINH CONSTRUCTION TECHNOLOGY MANUFACTURING AND TRADING CO., LTD. is a reputable unit specializing in supplying products made from Composite and Cast Iron materials: Manhole covers, drain grates, tanks, grating floors…. leading in Vietnam.

- Phamviet@xaydunghoabinh.com.vn

- Phamviet0809@gmail.com

- Hotline/Zalo: 0936 629 323

- Opening hours: 8:00 to 18:00