Standards for composite grating floor in industry

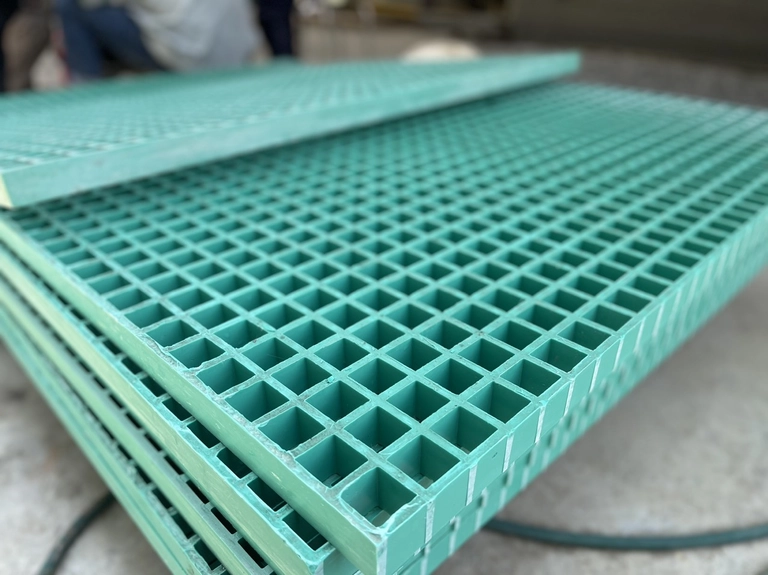

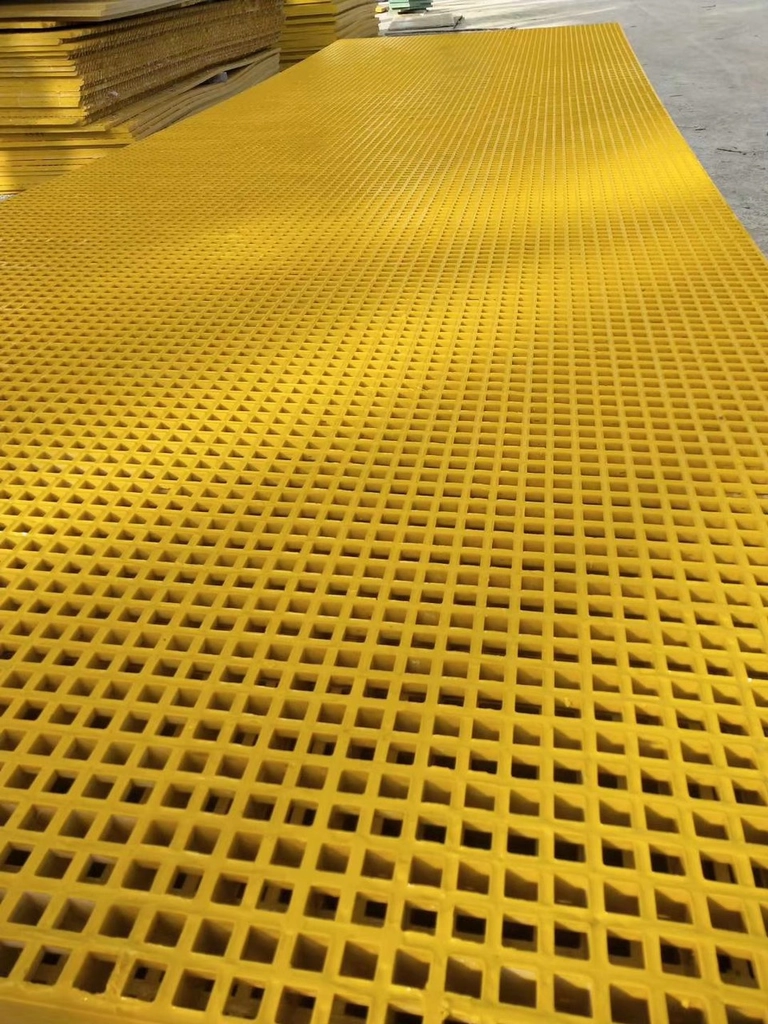

In the industry, choosing the right construction material not only helps optimize production processes but also ensures occupational safety. Composite grating floor is one of the preferred materials due to its superior advantages such as high durability, corrosion resistance, and light weight.

However, to ensure quality and performance, strict standards must be followed when manufacturing and installing composite grating floors.

A clear understanding of the advantages of composite grating floors and the methods for installation and maintenance according to standards will help businesses optimize costs and extend the product lifespan.

1. Material Standards

Fiberglass and polymer resin are the two main components in the process of manufacturing composite grating floors. Material standards require fiberglass to have high tensile strength and good corrosion resistance.

The polymer resin used in the flooring must have good heat resistance, chemical resistance, and mechanical strength. The quality of these raw materials directly affects the performance and lifespan of the floor.

This also plays a crucial role in the subsequent grating floor installation process, helping to ensure the robustness and safety of the structure.

1.1. Requirements for Durability and Lifespan

Fiberglass must meet the requirement for high mechanical strength to withstand impact forces during use. Additionally, polymer resin needs to have high stability, not undergoing change when exposed to chemicals in industrial environments, helping to extend the lifespan of the floor.

This is one of the advantages of composite grating floors compared to other materials like iron or steel.

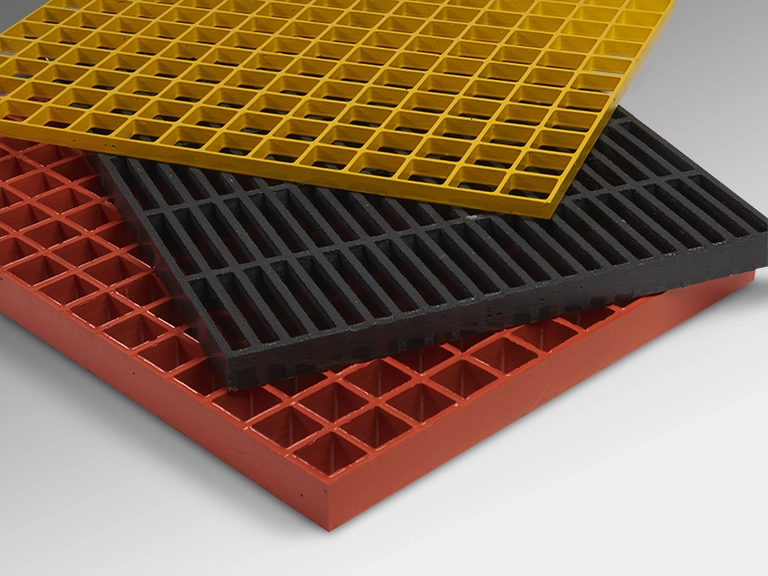

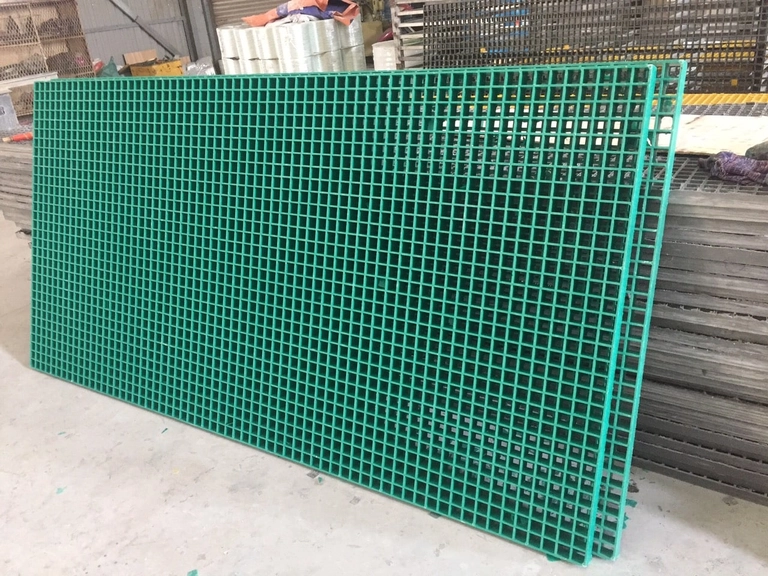

2. Size and Design Standards

The size and design of the flooring must comply with international standards such as ISO 14122-2 and ASTM E84. These standards clearly define the grid opening size, the thickness of the bearing bars (transverse and longitudinal), and the load-bearing capacity of the floor.

To ensure occupational safety, the floor surface needs to be roughened or feature ribs to prevent slipping.

2.1. Ensuring Safety in Design

The design of composite grating floors not only focuses on durability but also on the safety factor.

Roughening the surface or adding ribs helps increase grip, preventing slipping during use, especially in wet or oily environments.

This is crucial in the application of composite grating floors in heavy industries, where occupational safety is always the top priority.

3. Installation Standards

Floor installation must strictly adhere to guidelines regarding the spacing between supports, bolt sizes, and how the floor is fixed to the structure.

The spacing between supports must be carefully calculated based on the load-bearing capacity of the floor. Bolts and fixing accessories need to be made of corrosion-resistant material to ensure durability and safety in industrial environments.

In particular, the grating floor installation process must be carried out by specialized technicians to ensure maximum quality and safety.

4. Maintenance and Inspection Standards

To ensure the lifespan and performance of composite grating floors, periodic maintenance and inspection must be carried out according to standards such as ISO 9001.

Inspection should focus on areas such as corrosion resistance, load-bearing capacity, and the surface condition of the floor. Periodic maintenance includes cleaning the surface, inspecting, and replacing damaged sections to ensure occupational safety.

This not only helps maintain the floor's performance but also extends the product's lifespan, minimizing costs incurred from damage or replacement.

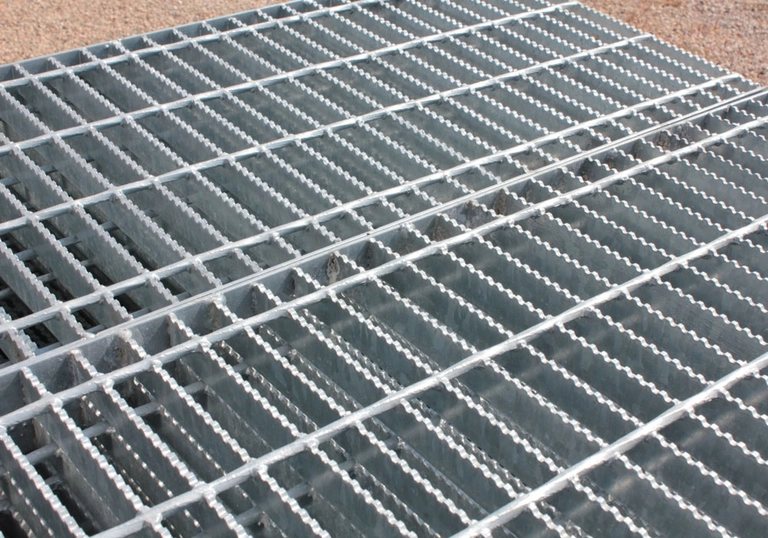

5. Advantages of Composite Grating Floors over Metal Floors

When compared to metal floors, composite grating floors have several superior advantages. Firstly, the corrosion resistance of composite flooring is much better than that of metal flooring, especially in harsh chemical environments.

Secondly, the light weight helps reduce the load on structures, making it easy to transport and install. Finally, the long lifespan and low maintenance costs save operating costs in the long run.

Additionally, composite grating floor maintenance is also simpler and less expensive, due to its non-rusting nature unlike metal floors.

5.1. Application in Harsh Environments

Composite grating floors are particularly suitable for environments with high humidity, chemicals, or harsh weather conditions. The ability to resist corrosion from the environment helps the floor maintain its durability over many years of use without frequent maintenance, completely different from metal floors.

This makes composite grating floors an ideal choice in composite grating floor applications at chemical manufacturing plants or wastewater treatment facilities.

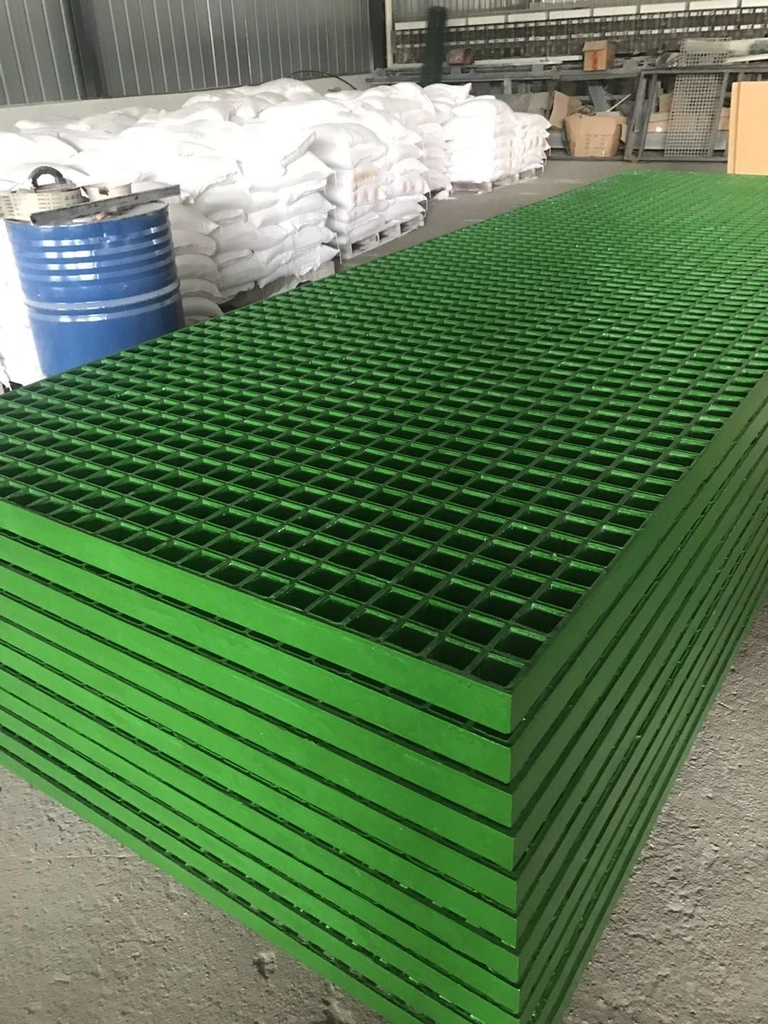

6. Applications of Composite Grating Floors in Industry

Thanks to their superior advantages, composite grating floors are widely used in various industrial sectors such as chemicals, oil and gas, food, and wastewater treatment.

Areas with high corrosive environments, such as chemical manufacturing plants or wastewater treatment facilities, often prioritize the use of composite grating floors to ensure durability and safety.

Notably, compared to other types of flooring, composite grating floor maintenance in these environments is also much easier, helping to save time and costs.

Compliance with standards when selecting and installing composite grating floors not only ensures performance but also increases lifespan and minimizes maintenance costs.

With their superior advantages, composite grating floors are increasingly used in industrial environments that demand high durability and safety.

Furthermore, understanding and correctly applying the grating floor installation process as well as composite grating floor maintenance will help optimize usage efficiency and extend the structure's lifespan.