Introduction to the 5 Operating Methods of HDPE Flap Valves

Overview of HDPE Flip Gate Valve

In this section, we will begin by understanding the concept, key features, and technical standards of the HDPE flip gate valve. This will form a solid foundation for diving deeper into the details in subsequent sections.

Concept and Features of HDPE Flip Gate Valve

The HDPE flip gate valve is a type of valve made from High-Density Polyethylene (HDPE) material for the valve body, with the main closing and opening component being the flip valve or flap gate. Due to its properties of resistance to forces, chemicals, and good oxidation resistance, the HDPE valve is suitable for many harsh environments such as wastewater, exhaust gases, and the chemical industry.

Key features include:

- The HDPE material has high durability, resistant to corrosion from chemicals, cleaning agents, and weather conditions.

- Simple structure, easy to install and maintain.

- Competitive pricing compared to metal valves.

- Suitable for use in systems containing or transporting highly corrosive liquids.

Understanding these features helps users choose the right valve for specific purposes, optimizing the system's operation efficiency.

Technical Standards of HDPE Flip Gate Valve

From a technical standpoint, the HDPE flip gate valve must meet both international and domestic standards to ensure safety, durability, and stable operation. Some common standards include:

- ASTM D3035 standard for HDPE pipes.

- ISO standards for industrial plastic valves.

- Vietnamese standards TCVN related to water materials and equipment.

Additionally, technical parameters to consider when purchasing the valve include:

- Maximum working pressure.

- Operating temperature.

- Size and connection type appropriate for the system.

- UV resistance, to adapt well to outdoor environments.

Understanding these standards ensures that the valve will operate efficiently when put into service, minimizing risks of malfunctions or leakage due to technical errors.

Popular Types of HDPE Flip Gate Valves in the Market

The market today offers various types of HDPE flip gate valves, classified based on their use, size, and structure into the following main types:

- Vertical neck HDPE flip gate valve.

- Horizontal neck HDPE flip gate valve.

- HDPE flip gate valve with automatic actuator integration.

- HDPE flip gate valve for large or small pipes.

Each type is suitable for different environments and operational requirements. Choosing the right type not only optimizes work efficiency but also reduces future maintenance and repair costs.

Structure and Operating Principle of the HDPE Flip Gate Valve

This section will specifically examine the design structure of the HDPE flip gate valve and the operating principle that enables it to control flow in the system.

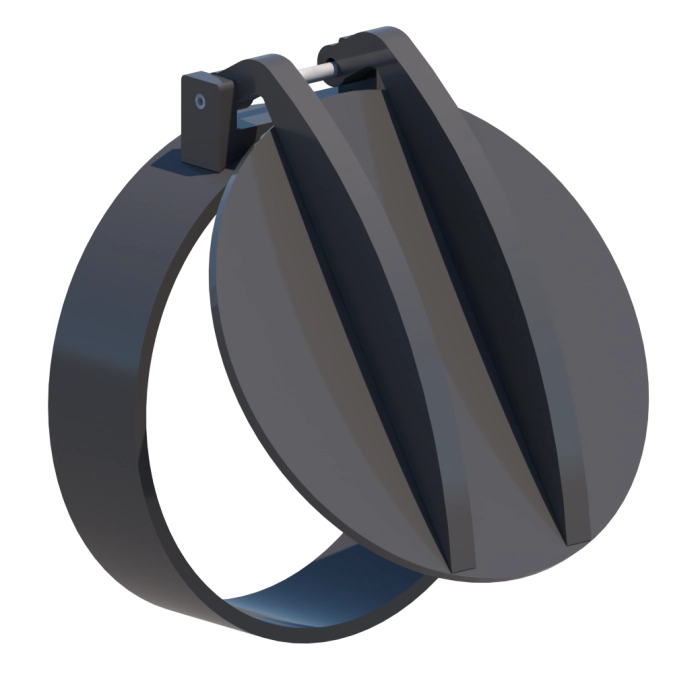

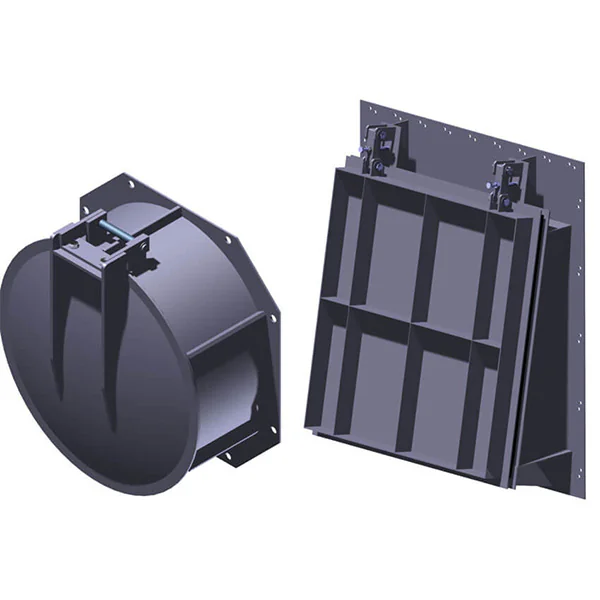

Structure of the HDPE Flip Gate Valve

The structure of the HDPE flip gate valve is quite simple but robust, consisting of the following main components:

- Valve body: The main load-bearing part, typically made from pure HDPE, resistant to corrosion and capable of withstanding high pressure.

- Valve flap or gate: The part that opens or closes to regulate flow, typically round or square in shape, securely attached to the valve shaft.

- Valve shaft: The central shaft connecting the valve flap to the actuator or manual handle, allowing the flap to rotate or flip.

- Guides and seals: Ensure no leakage of fluids when the valve is closed or opened.

- Actuator (optional): Can be a hand wheel, gear, or automatic actuator controlled by air, hydraulic, or electric mechanisms.

These components are designed for easy assembly, inspection, and cleaning. Selecting appropriate materials also extends the valve's lifespan and reduces issues like leakage or jamming.

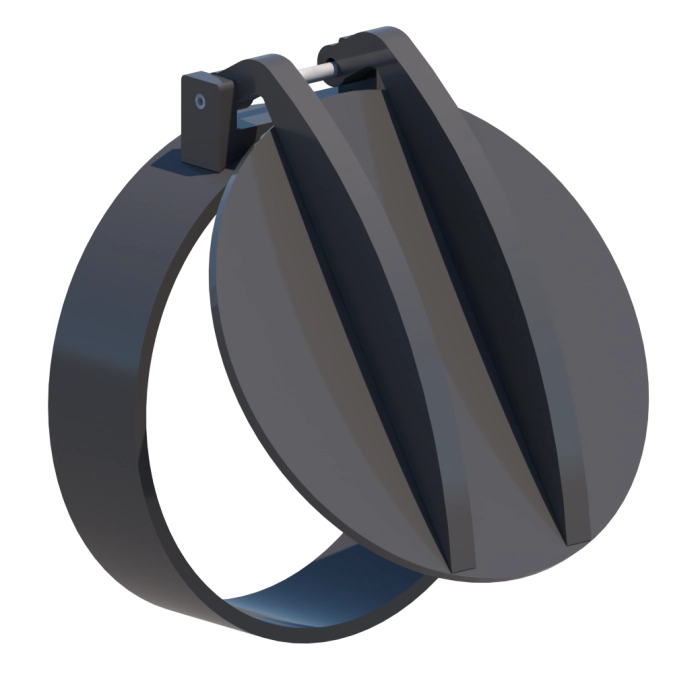

Operating Principle of the HDPE Flip Gate Valve

The operating principle of the HDPE flip gate valve is based on the flipping or rotating action of the valve flap to control liquid flow.

During operation, the user or actuator applies force to the valve shaft, causing the valve flap to flip open or close. When the flap opens, the flow through the pipe is allowed to pass, and when closed, the flow is completely blocked.

This provides easy and flexible control over the flow rate while ensuring safe and efficient system operation. The valve also has the ability to return to its original state when no external force is applied, maintaining system stability.

The benefit of this principle is that it allows the valve to operate smoothly even in harsh conditions, with minimal impact on the system and the surrounding environment.

Applications of HDPE Flip Gate Valves in Industry and Daily Life

This section focuses on introducing the common fields and environments where the HDPE flip gate valve is used, while analyzing the benefits brought by each specific application.

Applications in Water Supply and Wastewater Treatment Systems

In water supply systems, the HDPE flip gate valve is widely used to control flow, open and close pipe sections, or act as a discharge valve in water or wastewater treatment plants. Thanks to its corrosion resistance and oxidation protection, the HDPE valve is suitable for long-term operation in environments with low-quality water, chemicals, or bacteria.

In wastewater treatment, the valve plays a critical role in preventing leaks, maintaining sanitation, and controlling the treatment process. Especially in systems that require continuous operation and low maintenance, the HDPE valve is the optimal choice.

Applications in the Chemical and Gas Industry

In chemical industries, where liquids are highly corrosive to metals, the HDPE flip gate valve is an ideal solution. It not only resists corrosion but also maintains airtightness, preventing toxic gases from leaking into the environment.

Additionally, in gas systems or reactive gas environments, the HDPE valve helps ensure safe control, ease of operation, and maintenance.

Applications in Agriculture and Aquaculture

In agriculture, the HDPE valve is used to regulate irrigation water, control flow in irrigation systems, reservoirs, or aquaculture systems. The material's durability allows the valve to function well in wet environments exposed to soil, fertilizers, or agricultural chemicals.

In aquaculture, the HDPE flip gate valve helps maintain clean water systems, controlling water levels in ponds or fish tanks.

Benefits of HDPE Flip Gate Valves

- Corrosion-resistant, good chemical resistance.

- High durability, long lifespan, suitable for all environmental conditions.

- Simple operation, easy to install and maintain.

- Cost-effective, suitable for large and small-scale projects.

- Safe, environmentally friendly.

Conclusion

HDPE flip gate valves are important devices that contribute to enhancing efficiency and safety in many industrial and everyday systems. With a simple structure, flexible operating principle, and outstanding features such as corrosion resistance and high durability, HDPE valves have become the top choice in applications requiring long-term stability and reliability. Understanding the operation will help engineers and system managers optimize operation and maintenance, thereby improving work efficiency and ensuring environmental safety.

Conclusion

This article provides an overview of the HDPE flip gate valve – from structure and operating principle to practical applications. With its corrosion resistance, high durability, and ease of operation, this valve plays an indispensable role in water supply, wastewater treatment, chemical, gas industries, and many other fields. Choosing and using the right type of valve will ensure smooth, safe, and cost-effective system operation, contributing to the sustainable development of industrial and civil projects.