How are Cast Iron Tree Grates and Composite Tree Grates different?

Uses and Functions of Cast Iron and Composite Tree Grates

Cast iron tree grates (cast iron) and composite cast iron tree grates (composite cast iron) are two different processes used in the manufacturing of cast iron products. Below is the difference between these two processes:

Manufacturing process:

- Cast iron tree grates: The cast iron tree grate process is the traditional process in which molten iron is poured into a mold and allowed to cool and solidify. After solidification, the cast iron product will have a solid and quite hard root grate.

- Composite cast iron tree grates: The composite cast iron tree grate process is a more advanced process and uses new technology in manufacturing. Instead of using pure cast iron, this process combines the adhesion of cast iron with other binders such as epoxy resin, polymer, or fiberglass. The result is that the product will have a composite layer inside, providing better wear resistance and load-bearing capacity compared to pure cast iron.

Material properties:

- Cast iron tree grates: Pure cast iron has the property of high load resistance and crack resistance; however, it has poorer wear resistance and is easily oxidized and corroded in humid environments.

- Composite cast iron tree grates: Composite cast iron has improved properties compared to pure cast iron. With the composite layer inside, it has better wear resistance, can withstand greater impact and stress, and has better chemical and corrosion resistance in harsh environments.

Applications:

- Cast iron tree grates: Pure cast iron is often used in applications requiring high load resistance such as water tanks, drains, manhole covers, lampposts, and mechanical system components.

- Composite cast iron tree grates: Composite cast iron is often used in applications requiring a combination of good load resistance and wear resistance, such as gears and bearings.

Cost:

- Cast iron tree grates: The traditional cast iron tree grate manufacturing process uses pure cast iron uses pure cast iron, which can increase production costs. However, pure cast iron generally has a relatively low price on the market, so cast iron tree grate products can have a quite reasonable price.

- Composite cast iron tree grates: The composite cast iron tree grate manufacturing process uses advanced technology and special binders, so it may have a higher cost compared to traditional cast iron tree grates. However, the cost can be offset by the better performance and lifespan of the composite cast iron product.

Purpose of use:

- Cast iron tree grates: Cast iron tree grate products are often used in load-bearing applications, where high durability and good load resistance are required. Due to the load-bearing nature of pure cast iron, it is preferred in infrastructure construction, such as drainage systems, piping systems, and load-bearing mechanical components.

- Composite cast iron tree grates: Composite cast iron tree grate products are often used in applications requiring better wear resistance and corrosion resistance. Thanks to the composite layer inside, it is widely applied in heavy industries, such as the chemical industry, cement industry, and applications requiring high durability and wear resistance.

In summary, cast iron tree grates and composite cast iron tree grates have differences in manufacturing process, material properties, applications, and cost. The choice between these two methods depends on the specific requirements and conditions of each application.

Some of the most commonly used tree protection grates

Tree protection grates made of cast iron

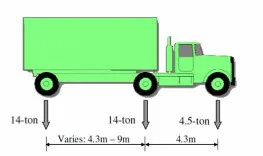

This type of tree grate is manufactured from ductile iron or gray cast iron material. For tree protection grates made from gray cast iron, they are usually very heavy. The surface of the cast iron grate, which is rough, is not highly aesthetic. Problems with installation as well as movement during periodic maintenance of the tree root are also difficult.

Currently, the cast iron tree protection grate most preferred by project constructions is still ductile iron. Because tree protection grate products made from ductile iron will have a smoother surface. They have higher aesthetics as well as lighter weight compared to gray cast iron. The process of transportation, cleaning, and installation is easy. However, one of the disadvantages of this type of cast iron tree protection grate is the cost. The expenditure required to obtain a set of tree protection grates is still very high.

In addition, tree protection grates made of cast iron are still frequently targeted by malicious individuals for theft.

Tree protection grates made of Composite

One of the biggest advantages of tree protection grates made from composite is the design versatility. Products made from composite are very light in weight. They are easy to move and install during the construction process. As well as during the maintenance and upkeep of the tree protection grate.

Furthermore, composite tree grate products have a much lower selling price compared to those made of cast iron. The surface of the composite tree protection grate is glossy and beautiful. It is diverse in color as well as style. Because of these outstanding properties, composite material tree protection grate products are used very frequently nowadays.

Tree protection grates made of steel

If comparing aesthetics and selling price, steel tree protection grates have the highest selling price. Because tree grates made of steel must have shaped steel bars cut. After that, they are welded together and galvanized. This incurs high labor costs and galvanizing costs. Because without an outer zinc coating, the tree protection grate is very susceptible to rust.

Secondly, steel tree protection grate products are very easily stolen. They have a high value and cannot be designed with an anti-theft feature like cast iron tree grates. Therefore, steel tree protection grates are very rarely used.

Installed and used in outdoor conditions, tree protection grate panels are usually manufactured from 3 main materials: cast iron, steel, and composite. In addition, due to the specific characteristics of each type of tree; and each project, many different tree protection grate designs are created; all of which have good functional utility as well as high artistic and aesthetic value.