HDPE Flap Valve: 5 Simple and Effective Installation Guidelines

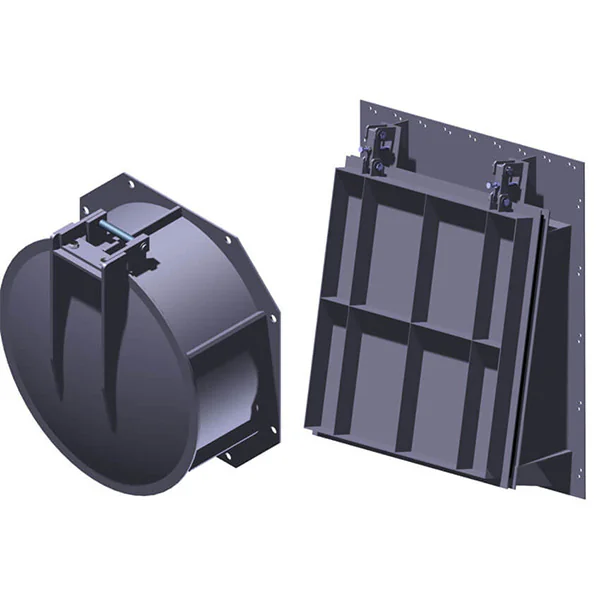

HDPE Flip Gate Valve

The HDPE flip gate valve is a valve that uses a flip gate to regulate the flow in piping systems. The HDPE (High-Density Polyethylene) material offers flexibility, excellent corrosion resistance, and is suitable for various environments, from clean water, wastewater to light chemicals. With its simple construction and ease of operation, HDPE flip gate valve has become a popular choice for industrial, agricultural, and residential applications.

Before diving into the detailed analysis of each component, it is important to understand the benefits of using HDPE flip gate valve:

- High oxidation and corrosion resistance due to the HDPE material.

- Good mechanical strength, capable of handling high pressure.

- Suitable for environments with high corrosion or chemicals.

- Easy installation and maintenance: simple design reduces time and effort required for construction.

With these features, the HDPE flip gate valve structure needs to be optimized technically to fully realize these advantages. Next, we will analyze the components of the valve in detail.

General Structure of HDPE Flip Gate Valve

The structure of the HDPE flip gate valve consists of main parts such as the valve body, gate, shaft, seal gasket, and connecting components. Each part plays a crucial role in the valve's operation, ensuring smooth operation, tight sealing, and long lifespan.

The valve body is typically molded as a single piece or assembled from smaller components, made from virgin HDPE material, which is resistant to impact, UV rays, and environmental agents. The gate is the part that controls the opening/closing of the flow, usually rectangular or circular in shape, depending on the design, but always designed to be easy to operate with minimal flow loss. The shaft connects directly to the gate and is fixed by bolts or joints, enabling easy opening/closing operations. The seal gasket helps maintain the tightness of the valve and prevents leakage during operation.

Although each valve model may have its unique design, the general structural principle remains the same, aiming to optimize performance and longevity.

Main Components in HDPE Flip Gate Valve

To gain a clearer view of the structure, let's dive into each specific component of the HDPE flip gate valve.

Valve Body

The valve body is the main part, housing other components and directly interacting with the fluid passing through the system. The HDPE material used for the valve body offers high corrosion resistance, making it suitable for various environments, including acidic or alkaline environments. The valve body is typically cylindrical, with connection ends that adhere to pipe standards such as flanges, steel wire connections, or welding. Additionally, the valve body is precisely manufactured to ensure tight connections, minimizing leakage during operation.

The valve body also includes partitions and drilled holes to secure internal components, making installation and disassembly easier, saving maintenance time.

Gate

The gate is the component that determines the valve’s ability to open/close, directly affecting the flow regulation. In the structure of the HDPE flip gate valve, the gate typically comes in rectangular or circular shapes, depending on the design and intended use. The gate is designed to have a suitable thickness, ensuring good resistance to pressure during opening and closing, and minimizing deformation or breakage during operation. The material used for the gate is usually HDPE or suitable composite materials, enhancing impact resistance and wear resistance.

The design of the gate to ensure ease of operation with minimal flow obstruction is key to improving the valve's operational efficiency.

Valve Shaft

The valve shaft is the connecting component between the handle or operating mechanism and the gate. In the structure of the HDPE flip gate valve, the shaft is made from durable materials such as stainless steel or high-strength plastic, ensuring long-term durability and resistance to corrosion. The shaft must rotate smoothly to ensure quick and precise opening/closing operations. Additionally, the shaft is equipped with auxiliary components like bearings to reduce friction and increase its lifespan.

The choice of appropriate materials for the shaft greatly influences the valve's pressure and temperature resistance.

Seal Gasket

The seal gasket plays an essential role in ensuring the valve’s tightness, preventing fluid or gas leakage during operation. In the structure of the HDPE flip gate valve, the gasket is often made from EPDM rubber, NBR, or TPE, which is resistant to chemicals and high temperatures, suitable for real-world applications. The gasket is designed to perfectly fit the body and gate components of the valve, ensuring easy installation and replacement when necessary. The gasket's wear resistance, aging resistance, and high-pressure tolerance help maintain long-term tightness, minimizing the risk of leakage and ensuring safety.

HDPE Flip Gate Valve

In the industrial sector, especially in water and chemical processing, HDPE flip gate valves have proven their high applicability due to the prominent features of HDPE material combined with optimized design. These valves are suitable for regulating flow in systems that require high durability and resistance to wear and corrosion. Additionally, models like HDPE flip gate valve D200 offer suitable choices for projects of varying scales, from small to large.

These valves are usually manufactured according to international standards, ensuring high quality while meeting safety and sanitation standards for sectors such as water supply and drainage, wastewater treatment, or light chemical industries.

Popular Types of HDPE Flip Gate Valves Today

Currently, the market offers many types of HDPE flip gate valves suitable for specific needs, such as:

- Classic HDPE flip gate valve

- HDPE flip gate valve with flange

- Large HDPE flip gate valves like D200, D300

- HDPE flip gate valve used in special environments such as heat-resistant, heavy chemical-resistant

Choosing the right type of valve depends on factors such as system pressure, temperature, type of fluid or gas to regulate, as well as the intended use of each project.

Advantages of HDPE Flip Gate Valve

- Good corrosion resistance: Not oxidized, suitable for use in highly corrosive chemical environments.

- High durability: Withstands impact and strong force, capable of continuous operation over a long period.

- Easy installation and maintenance: Simple design, convenient operation, and easy replacement of accessories.

- Reasonable cost: Compared to metal valves, HDPE flip gate valves are more affordable, fitting many project budgets.

- Safe and sanitary: Does not contaminate water sources or affect the quality of the flowing liquid.

Disadvantages of HDPE Flip Gate Valve

- Not suitable for flow regulation in systems that require precise control at high speeds.

- Can deform if exposed to temperatures beyond the HDPE material's limit.

- Difficulty in precise adjustments when the size is large or high sealing is required.

HDPE Flip Gate Valve D200

Among the types of HDPE flip gate valves, the HDPE flip gate valve D200 is a popular model suitable for systems requiring medium to large-scale operation. The D200 size refers to the nominal diameter of the valve being 200mm, making it ideal for urban drainage systems, wastewater treatment plants, or other industrial flows.

Technical Features of HDPE Flip Gate Valve D200

- Appropriate size: 200mm diameter, suitable for many large, medium, or small systems.

- Pressure resistance: Can handle high pressure, typically operates well at around 10 bar or more.

- Material: Entire valve body and gate made from virgin HDPE, ensuring durability and corrosion resistance.

- Sealing design: EPDM or TPE rubber seal gaskets ensure no leakage during operation.

- Easy installation: Standard connections, compatible with international standards.

Advantages of HDPE Flip Gate Valve D200

- Suitable for large systems that require high durability and pressure resistance.

- Cost-effective maintenance and replacement due to HDPE's excellent oxidation resistance.

- Optimized design, making it easy to operate and maintain quickly.

- Environmentally friendly, does not release toxins during use.

Applications of HDPE Flip Gate Valve D200

- Urban water supply and drainage systems.

- Industrial wastewater treatment plants.

- Natural and artificial irrigation systems.

- Small-scale hydroelectric and irrigation projects.

- Light chemical and clean water treatment plants.

Considerations When Choosing HDPE Flip Gate Valve D200

- Check system pressure to select the appropriate valve type.

- Choose the right connection type for the pipeline system.

- Ensure the seal gasket is suitable for the liquid or gas being regulated.

- Choose a reputable supplier, ensuring quality and after-sales service.

Conclusion

The structure of the HDPE flip gate valve reflects an optimized design to fully utilize the standout features of HDPE material such as corrosion resistance, durability, and easy installation. Each component, such as the valve body, gate, shaft, and sealing gasket, is carefully manufactured to ensure smooth, tight, and long-lasting operation. Among these, the HDPE flip gate valve D200 is a typical product ideal for large systems requiring durability and pressure resistance. Understanding the structure and technical features of these valves will help engineers and managers choose the optimal solution, improve system efficiency, and minimize risks and maintenance costs during usage.