Ductile Iron Manhole Cover Production Process

I. Introduction

The **ductile iron manhole cover** is a vital product in urban drainage systems, manufactured from ductile iron—a durable, high load-bearing, and wear-resistant material. The production process for ductile iron manhole covers involves many stages, from design and raw material preparation to manufacturing and quality inspection.

II. Product Design

1. Customer information collection

Technicians collect product requirements from the customer to ensure the manhole cover meets the exact specifications.

2. Determining size and shape

Based on the requirements, the **size and shape** of the manhole cover are determined, including diameter, height, and the position of the drainage holes.

3. Mold design

The design team creates a **mold** based on the determined sizes and shapes. This mold will be used for casting the product.

4. Developing the production plan

The production plan includes technical specifications, necessary raw materials, and the manufacturing procedure.

III. Product Manufacturing

1. Raw material preparation

The main raw material for manhole cover production is **ductile iron**, an alloy containing iron, carbon, silicon, manganese, and other elements.

2. Mold and equipment preparation

The mold is prepared, and equipment such as **casting machines** and **furnaces** are readied to begin production.

3. Product casting

The casting process begins with pouring the molten ductile iron into the mold. The iron must be poured at a precise temperature and using the correct technique to ensure the product has high durability and accuracy.

4. Product heat treatment (Annealing/Curing)

After casting, the manhole cover will undergo a **heat treatment** (such as annealing) to increase its hardness, durability, and eliminate small defects like cracks or scratches.

5. Product finishing

After heat treatment, the product is processed: excess parts are cut off, the surface is ground smooth, and polished to meet aesthetic standards.

IV. Product Quality Inspection

1. Size inspection

The inspection team checks the **dimensional accuracy** of the product to ensure it meets the design standards.

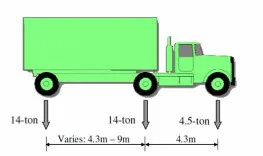

2. Load-bearing capacity test

The ductile iron manhole cover is tested for its **load-bearing capacity** to ensure it meets real-world usage requirements.

3. Durability test

Technical teams conduct tests by applying different loads to the product to assess its **durability**.

4. Hardness and aesthetic inspection

The **hardness** and moisture of the product are checked to ensure it meets the required stiffness. Simultaneously, the surface, color, and shape are evaluated to ensure the product has high **aesthetics**.

V. Packaging and Transportation

After quality inspection, the product is carefully packaged using protective materials and labeled for safe **transportation** to the customer.

VI. Conclusion

The production process of ductile iron manhole covers is a complex procedure that demands high precision and expertise. From the design, casting, heat treatment, to quality inspection, every stage requires meticulous attention to create a product that meets standards for **quality, durability, and aesthetics**.