Compare Cast Iron and Composite Manhole Covers

h2>Introduction to Cast Iron and Composite Manhole Covers

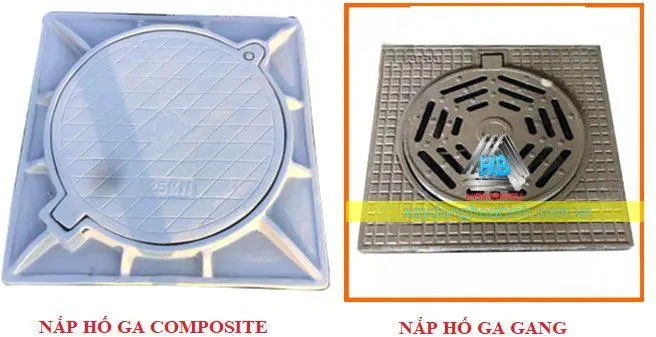

Manhole covers are an important part of the drainage system, used to cover and protect pipes from debris, impurities, and waste accumulation. The most commonly used manhole covers are cast iron and composite manhole covers. In this article, we will compare cast iron and composite manhole covers in terms of features, advantages and disadvantages, cost, durability, and other factors to help you choose the right type for your needs.

Characteristics of Cast Iron Manhole Covers

Cast iron manhole covers are a special product made from cast iron, offering high hardness and load-bearing capacity. They are impact-resistant, durable, able to withstand high temperatures, and resistant to environmental factors such as water, rain, dust, and UV rays. Additionally, cast iron manhole covers have anti-slip properties and can withstand heavy impacts from cars and large trucks. They also have high durability and can be used in harsh environments without damage.

However, some drawbacks of cast iron manhole covers include their heavy weight, making them difficult to move and install. They require special tools and manpower for installation and maintenance. Furthermore, cast iron manhole covers may generate noise when vehicles pass over them and can corrode over time.

Characteristics of Composite Manhole Covers

Composite manhole covers are a newer product made from fiberglass, carbon fiber, and polyester resin, offering durability and hardness similar to cast iron manhole covers but with a lighter weight. They have high load-bearing capacity, impact resistance, and are corrosion-resistant with high durability. Composite manhole covers also withstand high temperatures and environmental impacts like water, rain, dust, and UV rays.

Some advantages of composite manhole covers are that they are lighter than cast iron manhole covers, making them easier to move and install. They do not create noise when vehicles pass over them and have anti-slip properties. Composite manhole covers come in various colors and can be custom-designed to match the surrounding environment.

However, some disadvantages of composite manhole covers are that they tend to be more expensive than cast iron manhole covers, especially when ordered in small quantities. They also have lower durability when impacted by large trucks and require more frequent maintenance.

Price Comparison

In terms of price, composite manhole covers are generally more expensive than cast iron manhole covers. The price of composite manhole covers depends on various factors such as size, material type, and order quantity. However, if ordered in bulk, the price of composite manhole covers can be reduced and become more competitive compared to cast iron manhole covers.

Durability

The durability of cast iron and composite manhole covers depends on the environment, load capacity, and frequency of use. However, cast iron manhole covers are generally more durable than composite manhole covers, especially when used in harsh environments and under heavy loads. Cast iron manhole covers also have higher durability when subjected to large trucks.

Nonetheless, composite manhole covers also have high durability and are corrosion-resistant. They can withstand environmental impacts like cast iron manhole covers and are widely used in renewable energy applications and other industries.

Conclusion

Here are some key points highlighting the differences between cast iron and composite manhole covers. Based on factors such as price, durability, and corrosion resistance, cast iron manhole covers are commonly used in construction and public infrastructure applications, while composite manhole covers are favored in environments requiring high durability and corrosion resistance.

When selecting a manhole cover for a project, project managers and investors need to consider factors such as price, durability, and corrosion resistance to make the best decision for their projects.

Additionally, to ensure the safety and reliability of manhole covers, project managers and investors must comply with regulations regarding the design and installation of manhole covers. These regulations are usually set by organizations and regulatory agencies such as the Ministry of Construction and Industry, Standardization Organizations, and local management authorities.

Overall, both cast iron and composite manhole covers have their respective advantages and disadvantages. The choice of manhole cover depends on the project’s requirements and factors like price, durability, and corrosion resistance.

However, composite manhole covers can be considered a suitable choice for projects that require higher durability and corrosion resistance. They are ideal for environments such as industrial zones, areas prone to high corrosion, or in applications where ease of installation and transportation are key requirements.

Furthermore, composite manhole covers offer several advantages over cast iron manhole covers. One of the major benefits is their better corrosion and chemical resistance. They also perform better in wet environments, areas with heavy dust, and other harsh environmental factors.

Composite manhole covers can also be designed to withstand higher loads compared to cast iron manhole covers of the same size, which can help reduce costs for projects requiring heavy loads, such as roads for heavy traffic.

In addition, composite manhole covers have noise and vibration reduction capabilities. This can help minimize acoustic impact on roadways and reduce the negative impact on the living environment of local residents.

Aesthetically, composite manhole covers can also be designed to suit various living and working environments. They can be produced in a range of colors and patterns, allowing them to blend harmoniously with the landscape.